2022 Candle Production Line 12 Nozzle Filling Machine Conveyor Belt For Soy Honey Wax Beeswax Huge Order YIDE Manufacturer

- Overview

- Parameter

- Inquiry

- Related Products

Yide

Presenting the 2022 Candle Production Line 12 Nozzle Filling Machine Conveyor Belt for Soy Honey Wax Beeswax Huge Order YIDE Manufacturer a game-changing device that revolutionizes the method actual are designed! This production line consists of the 12 Nozzle Filling Machine and a Conveyor Belt that will work in tandem to enhance efficiency and effectiveness.

The 2022 Candle Production Line 12 Nozzle Filling Machine Conveyor Belt for Soy Honey Wax Beeswax Huge Order YIDE Manufacturer is simply an instrument state-of-the-art fills up to 12 jars or containers with simplicity and accuracy. Made from the item quality materials being greatest, this device was made to final which is perfect for people who create candles in bulk. It could manage a selection of wax kinds, including soy, honey, and beeswax, rendering it a versatile device for anyone in the candle-making trade.

The Conveyor Belt could be crucial within the manufacturing line because it holds the containers towards the stuffing machine without the intervention handbook. This allows smooth and seamless transfer, making it possible for quicker manufacturing times and minimal disruption. The conveyor gear is customizable to lengths that can easily be varied, making certain it could accommodate certain requirements of any size manufacturing line.

The 2022 Candle Production Line 12 Nozzle Filling Machine Conveyor Belt for Soy Honey Wax Beeswax Huge Order YIDE Manufacturer will be the ultimate solution for those who wish to just take their candle manufacturing to some other location degree whether you might be your enterprise owner if not an enterprise big. This device is fantastic for those who have huge requests to meet, making certain dates that are due to be met with simplicity.

Probably one of the most appealing facets of this manufacturing line will be the fact that it is created by Yide - a dependable and name brand reputable in the industry. Yide is a well-known candle-making gear that has been serving the industry for many years. You'll be able to be confident you will be finding an item supported by the brand name's track record of quality whenever you decide on the Yide 2022 Candle Production Line.

Name | Automatic candle making production line |

Power | 26KW |

Voltage | 380V 60hz three phase |

Filling nozzle | 12 nozzles*2 sets |

Filling Speed | 8000-10000pcs/hour |

Filling volume | 0-1000g |

Convey belt size | Standard 24Meter length*1.2m width |

Material | machine body ss201 and contact material ss304 |

Machine Size | 24000*1200*1700MM |

Weight | 5Ton |

Customize | Yes |

Automatic candle making production line

The line is used for the production of glass candles i.e. tealight or votive ,glass cup candles.

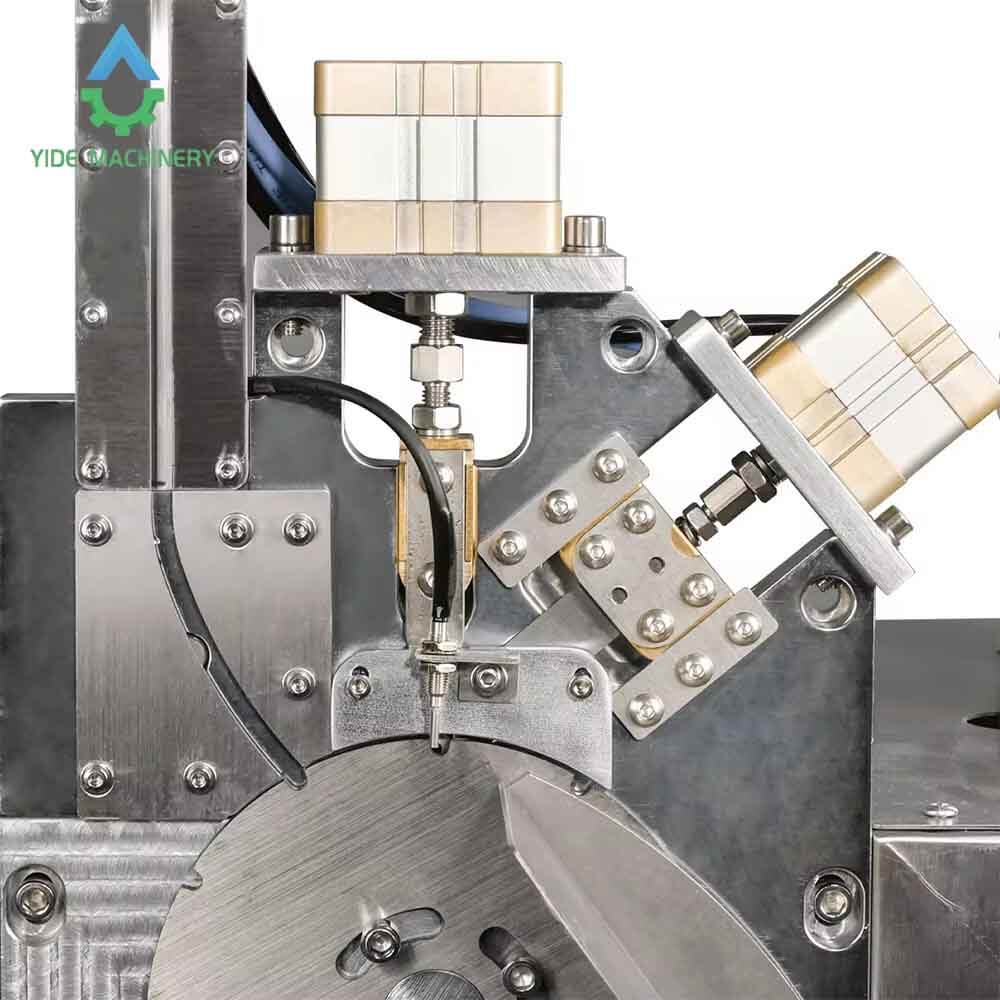

It is a fully automated machine which the main element is a mesh conveyor. The conveyor transports several containers in a row at the same time, directly under the set of dosing nozzles, fixed in the dosing station, connected with the paraffin melter. As a standard, the line is equipped with two dosing stations that operate the main chamber and the so-called refills. The filled containers are cooled with efficient fans, optionally air-conditioning system may be used. The length and width of the sequence (number of nozzles in a row) is adjusted individually to the needs and size of the Customer's production plant.

Possible configuration:

• wick inserting machine;

• automatic line loading and unloading system;

• swivelling wheels and conveyor belts;

• container pre-heating system;

• mesh conveyor;

• dosing stations with melters;

• fan stations;

• mesh cleaning system from paraffin;

• labelling machine;

• packing machine.

After the cup is preheated, it enters the filling system.

Set the filling capacity and other relevant data in the PLC system, and fill 12 cups at a time.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SK

SK

SL

SL

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

LB

LB