Unveiling the Benefits of 2 in 1 Cotton Wick Machine

Since the textile industry has gone through a significant changes towards automation and it is starting to affect different phases of manufacturing in recent years. An interesting innovation in this time for the cotton wick making facility is 2 in 1 Cotton Wick machine, a Novel type of machinery which makes and breaks with the era technology.

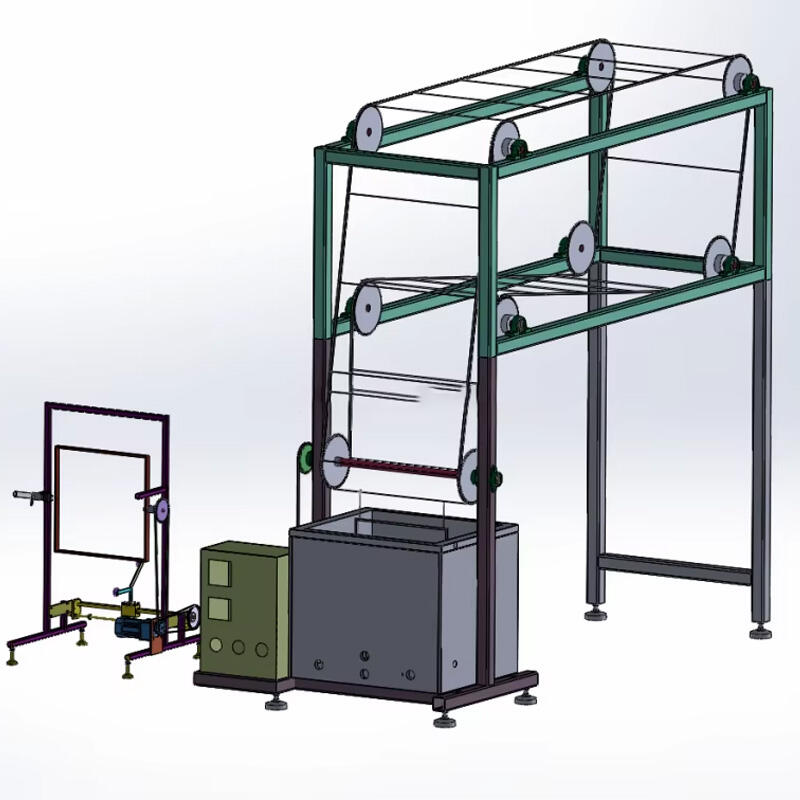

2 in 1 Cotton Wick Machine is made to complete the industry of manufacturing cotton wicks and make it an easy process. A multitask machinery that has two important segments namely carding machine and wick cutter, it helps in overall productivity & efficiency of the textile industry.

The primary function of the carding machine is to process raw cotton, more precisely picking out longer fibers from it and making them into a continuous sheet form i.e. breath strip called web as shown in below fig. This is where the wick cutting machine comes into play, dividing the cotton sheet as needed (as per what size of a wick will be required for candle production). This integration is not only transparent in production but also brings a host of advantages for manufacturers.

The 2 in 1 cotton wick making machine has a major advantage that is its performance has risen a lot. This machine allows to deliver a massive volume of cotton wicks in the shortest possible time which streamlines production, reduces total manufacturing time and increases efficiency.

What is more, the 2 in 1 machine uses a user-friendly interface which means that it can be easily used by anyone. Made of Tough & Superior Quality Material, This machine is built to last long and thus reduce maintenance costs for manufacturers.

The latest technology in cotton wick machines is the 2 In 1 Cotton Wick Machine which combines two different machinery into a single machine as one unit, it saves space and cost of production. This guaranties the device high performance because using its carding machine it can very cleanly unusable and dirty raw cotton into a continuous sheet of cotton that is flawless, while with wick cutting machines outputs almost any size of voile.

The Revolution Of The 2 in 1 Machine (YOURS FOR FREE)

The cotton wick machine 2 in 1 is an ideal solution for anyone seeking to enhance their offering with production capabilities that are a lot more advanced and above everything else, efficient. This machine provides growing accuracy and also comes with the capacity to manufacture wicks in a variety of sizes, which can be customized further if needed by makers who are small-scale or either large scale as well.

Finally, the 2 in 1 cotton wick machine displays an excellent achievement based on efficiency and optimizes manufacturing flexibility within a space-saving layout. With more and more industries incorporating this groundbreaking tech, the advantages of cost-effectiveness, better productions as well as streamlined processes are being witnessed making a 2 in one machine an asset among textile manufacturers.

Dongguan Yide Machinery Co.,Ltd specializes production candles. most popular products wax melting tank, wax-filling machine wicking machines. We've more 100 2 in 1 cotton wick machine, two fully automatic lines always available.

Providing 2 in 1 cotton wick machine warranty period as well lifelong maintenance program, expert inspection videos pictures will sent out clients prior shipment. After-sales problems will resolved within hour solution will offered within 24 hours. clients impressed skilled team foreign trade as well friendly service. We have skilled RD department will turn ideas into functioning machine. our production team responsible each steps your production until get product.

2 in 1 cotton wick machine equipment constructed food grade stainless steel 304,anti corrosion,antirust resistant high temperatures.standard motor replaced servo stepper motor order increase precision efficiency. pump made stainless steel food grade 316, not steel plastic.have different sizes pumps, such 4L, 6L, 10L 20L meet different filling range. PLC touch screen makes easy set parameters, such filling frequency, filling speed as well temperature requests more. There's broad selection candle equipment available not just semi-automatic, as well fully-automatic one. machines all updated details, be more flexible more stability.

Three 2 in 1 cotton wick machine employees 8 steps quality checks ensure machine 100% reaching standards safety using.With experienced RD team comprising 5 members offer custom solution 48 hours. perfect machine your candle-making business. We able build machine precisely your specifications, just meet requirements