Eons have passed since the handcrafted era of generations in the past. Today, this has left us with a new era where the distinction between technology and artistry in candle creation no longer exists. Yide candle filling machine which are a boon to manufacturers of candles when they try to infuse practical efficiencies on their production lines without tampering with what makes handcrafted candles unique. It is a perfect blend which allows manufactures to produce 100 shapes and size candles with different available scents need for consistency and speed in mind.

These machines can track precisely how and when every bit of wax is poured, cooled to perfection. It helps keep each batch consistent without relying on human judgment. These are additives of soap making color, scent and even things like fun embeds. Yide wax filling machine are what elevate the candle-making from an artisan process to a competitive business scale and quality yet still retain their traditional uniqueness.

Efficiency is the cornerstone of all automatic candle fill machines. This makes these machines very helpful in saving the labor through automatically doing all that was up to now done through manually. A common filler essentially prevents waste, ensuring each candle comes perfect with the right amount of wax. Yide candle wax filling machine work endlessly and boosts the output capacity so that a candle producer can better deal up with expanding market requirements.

The newer generations of candles will be brought to perfection by a high-tech machine and the days of hand pouring are slowly being replaced. Modern automatic candle filling machine control panels allow candle craftsmen to produce intricate, multi-scents with ease instead of sticking solely to their best-sellers and risking a more limited range into the offering in exchange for broader established customer base.

The coolest part of these candle making automation is that they can use customized smells and custom designs. Premium systems are designed to combine multiple oils allowing for a unique scent experience catering to personal preferences. This candle filling equipment simplifies mold production from modular molds and with them people can make other rare shaped candles in addition to traditional pillars or intricate geometric designs. Many businesses can do the specialization in custom products which gives them a competitive advantage over competitors.

Dongguan Yide Candle fill machine Co.,Ltd specializes production candle machines. most popular products wax melting tank, wax-filling machine, wicking machines. We more 100 semi automatic candle machine stock, two fully automated lines available.

Three QC employees, eight stages quality control, safety tests ensure machine compliance guidelines safety use.We a group five professionals who offer you custom solution just 48 hours. ideal equipment candle manufacturing business. We Candle fill machine build machine meet requirements.

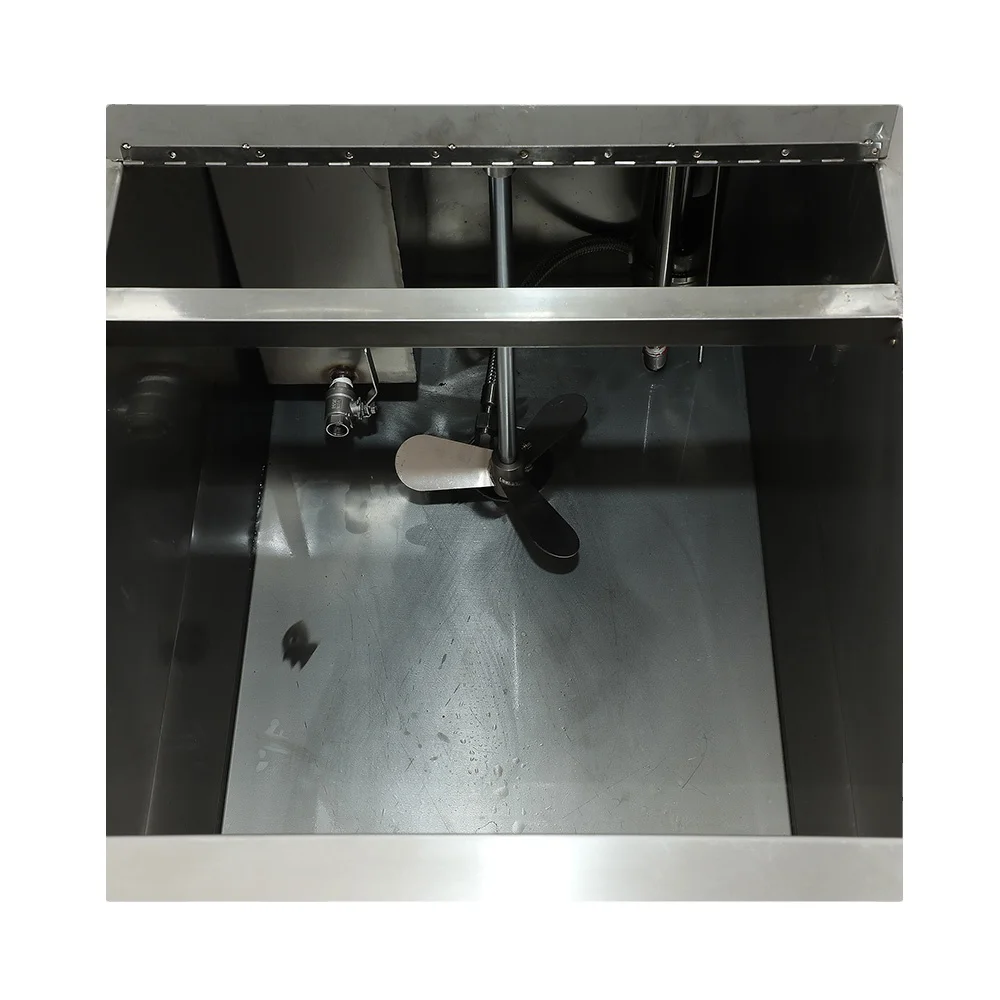

Candle fill machine equipment constructed food grade stainless steel 304,anti corrosion,antirust resistant high temperatures.standard motor replaced servo stepper motor order increase precision efficiency. pump made stainless steel food grade 316, not steel plastic.have different sizes pumps, such 4L, 6L, 10L 20L meet different filling range. PLC touch screen makes easy set parameters, such filling frequency, filling speed as well temperature requests more. There's broad selection candle equipment available not just semi-automatic, as well fully-automatic one. machines all updated details, be more flexible more stability.

Candle fill machine after-sales addressed one hour. customers appreciate experienced team foreign trade considerate service. also have highly skilled RD department which transform ideas working machine. production department responsible for step your production process until receive goods.