History speaks about the love that people have for candles and how they use candles throughout all times. They can make a place warm and welcoming just by lighting the room. Back in the day crafting candles was an arduous chore that took a lot of time and work. The traditional craft of printing, however But with the advent of averaging candle making machine this changed traditionality into both handy and time-efficient at its best.

This machine for producing candles comes with a plethora of advantages that make it easy to produce candles. One of the best parts about this process is how drastically less time and energy it takes to make candles. The machine used here help in the manufacturing process and it is capable of creating a lot large quantity of candles at once, fewer times. It also maintains the consistency of candles in both appearance and quality, a feat that can be quite difficult to do with handcurfted candles. Moreover, the machine will lower an amount of necessary competence as used for developing raw materials and also providing opportunities to broader ranger of people who are familiar with the candle making business in more realistic manner.

This advanced machine introduced the revolutionary change in candle making industry. Using state-of-the-art technology, the machine ensures that every candle made is of equal quality no matter how many you produce. The innovative design makes it easy to make candles of the desired size and shape (this part was messy with traditional methods). The candle making machine can be used to craft all kinds of candles (from long/pillar/stick/aromatic/flower pot, only your imagination is the limit) with speed.

Safety is a Must with the Candle Making Machine

As candles making require to deal with melts, a stove heating up to much extra high temperatures compared this toy furnace an individual utilizing tangled base excess on open fire it is impossible truely competitive not following standard. Candle Making | Traditional methods of making candles are liable to burn risk, but not with the use of a machine. Further, it reduces the exposure to pollutants that may be released in making a candle so as not only preservative of people but also from an ecological aspect.

Candle making machine is simple for beginners without any experience in candle production. Start with the wax type you chose for your candles in a pot suitable for meltingredux Next, you will want to carefully pour the melted wax into one of the containers on that same machine. Turn on the machine and adjust temperature levels as appropriate. The machine will start crafting candles that you want by pouring wax into molds.

This machine is accessed at different service and quality assurances to ensure customer satisfaction as the candle making machine. Warranty of up to 12 months from Manufacturers with the best Customer support services. Design with quality, this machine lasts longer along time performing efficient. It is therefore safe to say that the machine will provide customers with a return on investment by producing consistent and high-quality candles, they can then sell from their businesses.

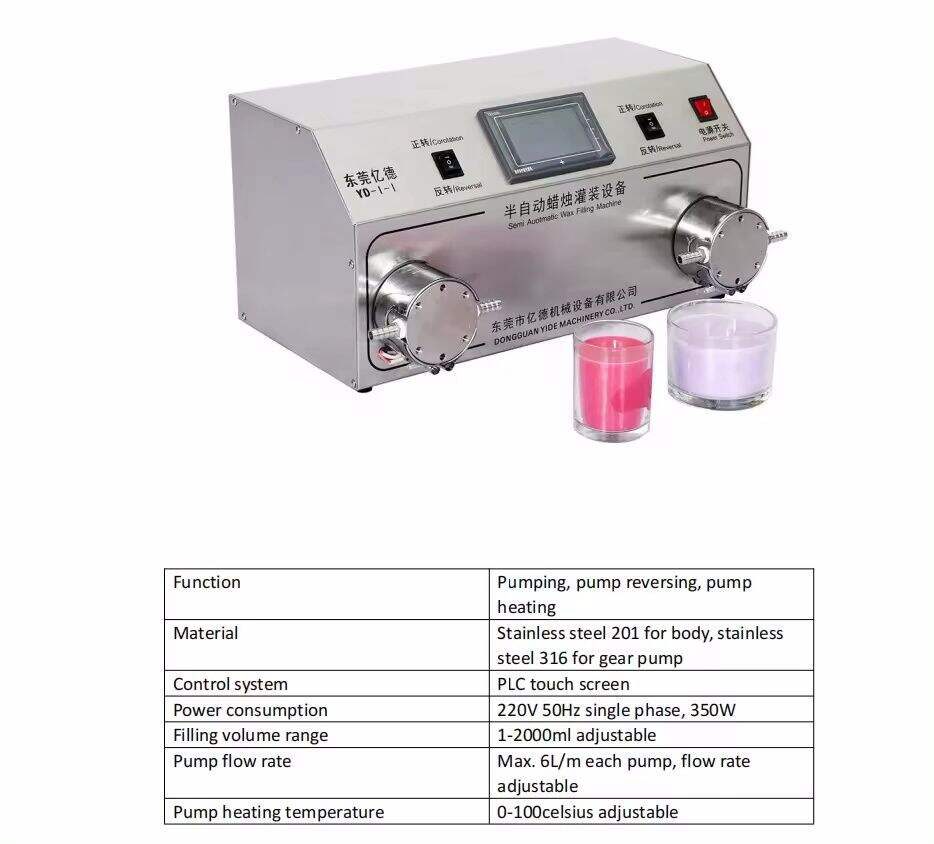

equipment made food grade stainless steel 304, anti corrosion, antirust resistant high temperatures.order ensure precision effectiveness, stepper motor servo motor replaced normal motors. pump constructed stainless steel food grade type 316, metal plastic.There variety sizes pumps, 4L/6L/10L 20L accommodate different filling capacities. PLC touch screen desgin easy set parameters, such filling rate, filling distance temperatures, filling speed more. full range candle-related equipment selected, just Candle light making machine automatic type, also fully automated types. machines been upgraded make more flexible durable.

3 QC employees 8 steps testing quality ensures machine completely meets requirements safety use.We a team five professionals provide customized solution Candle light making machine hours. Perfect machinery candle-making business. We build machine according requirements.

Dongguan Yide Candle light making machine Co.,Ltd specializes production candle machines. most popular products wax melting tank, wax-filling machine, wicking machines. We more 100 semi automatic candle machine stock, two fully automated lines available.

Providing Candle light making machine warranty period as well lifelong maintenance program, expert inspection videos pictures will sent out clients prior shipment. After-sales problems will resolved within hour solution will offered within 24 hours. clients impressed skilled team foreign trade as well friendly service. We have skilled RD department will turn ideas into functioning machine. our production team responsible each steps your production until get product.