The candle making machine automatic is an automated device, which was created especially for easy processing of the process in solution. This eaxctly dwarfs the proces of making candles by hand and in turn offers a machine method to thousands of madeby end sortation which is what makes this produxtion.process so successful. This machine automates all the steps of melting wax, pouring that hot liquid into mold and letting it cool so this time and effort-saving way will not only ensure consistent every single candle result.

There are many advantages to using a fully automatic candle making machine. For starters, it saves time and removes hard manual work of traditional candle making methods. This machine would create many candles in a fraction of the time it takes to do them by hand. Also, it ensures consistency in the size color and smell of every candle. The mechanisms of Manbo make sure that every candle produced is exactly the same in terms, dimensions. In addition to that, it provides you with more control over the candle-making process - experimenting on scents, colors and sizes. Finally, because this machine is an investment it only requires your money one time and you will be saving a lot on wax wastage and labor.

Running a candle making machine automatic is an easy process. First, make sure the machine is connected to a power source. Then you will need to fill up the wax melting container of vessel with previously prepared a pure aromatic soy candles and start heating it. When the wax is completely melted you can start adding any scents, colorants or additives that you like. So, you need to pour the wax carefully in your involved molds. 4. When hardened, place in a cool location until the wax has completely set for easy removal from your molds These candles will be pulled from the molds by a separate machine, streamlining the rest of the candle-making process.

This automatic candle making machine offers several safety features to ensure both user and the quality of candles being made are protected. These characteristics are regulated temperature to inhibit overheating, automatic shut-off mode in case some failure occurs and an alarm which warns users about possible problem The machine is also cleaning friendly so that you have no worries of contamination and give best quality standards to the candles.

The quality is exceptional with this candle making machine automatic, and it shows (year after year) that many professionals find other machines to be lacking in overall craftsmanship. These machines are created to endure the test of time and they will produce candles in different shapes, sizes along with colours. For multiple pours and different types of candles, some even have temperature-adjustable pouring spouts or refrigeration systems. They also offer excellent customer support and warranties for manufacturers to ensure a satisfying experience.

Offering one-year guarantee lifelong maintenance service, professional inspection videos images will emailed clients prior shipment. After-sales problems will resolved within hour solution will offered Candle making machine automatic hours. clients impressed skilled team foreign trade as well considerate service. We have experienced RD department will your ideas a working machine. And production team responsible each stage production point you receive product.

Three Candle making machine automatic employees 8 steps quality checks ensure machine 100% reaching standards safety using.With experienced RD team comprising 5 members offer custom solution 48 hours. perfect machine your candle-making business. We able build machine precisely your specifications, just meet requirements

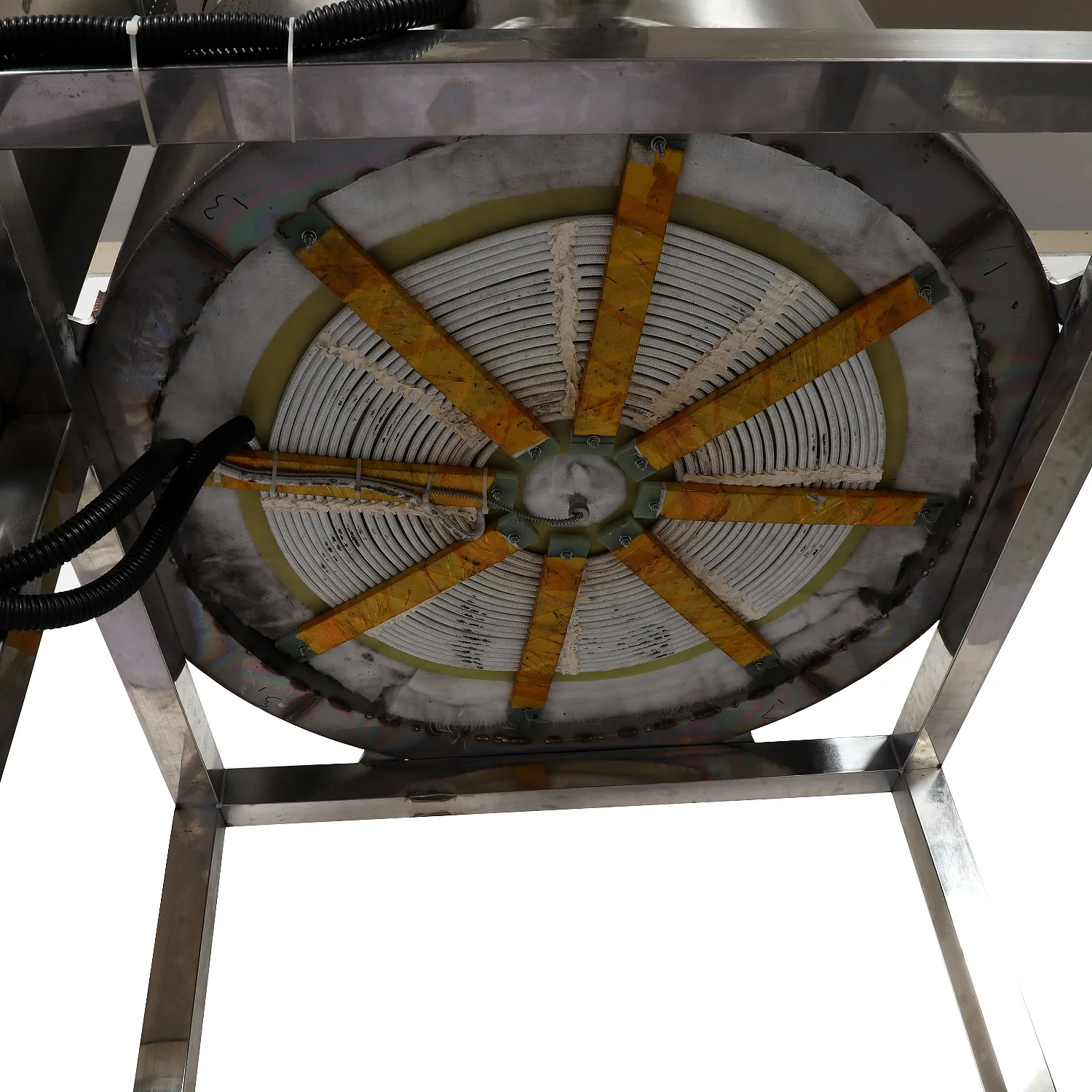

All equipment constructed food-grade stainless steel 304,anti corrosion,antirust resistant high temperatures.ensure efficacy precision efficiency precision, stepper motors servo motor used instead regular motors. pump constructed food grade stainless steel type 316, not steel plastic.We different sizes pumps, including 4L,Candle making machine automatic 10L 20L 20L used fill wide range. PLC touch screen makes simple set parameters, such as filling frequency, filling speed temperature request, so on. There's complete variety candle equipment choose not only semi-automatic type also fully-automatic type. machines upgraded terms detail, allowing to more flexible have more stability.

Dongguan Yide Machinery Candle making machine automaticLtd focused production candle machines. main product wax melting tank, wax filling machine wick machine. factory cover area approximately 2,500 square metres, standard semi-automatic candle machine over 100 sets. fully automated line always two sets stock. We have commitment sharing most efficient engineering solutions candle manufacturers around world.