Home & FamilyThe Changing Face Of Candle Craft: Electric Candle Making Machine

I love candles, but I hate how messy and time consuming the traditional candle making process can be. Maybe next time we will say that you want to watch one of the electric candle making machines. Every so often in the world of candle-making, a new product comes along that is as simple to use as it is transformative for one and all. Further to the remaining part, we will see why is an electric candle making machine important for your home or business

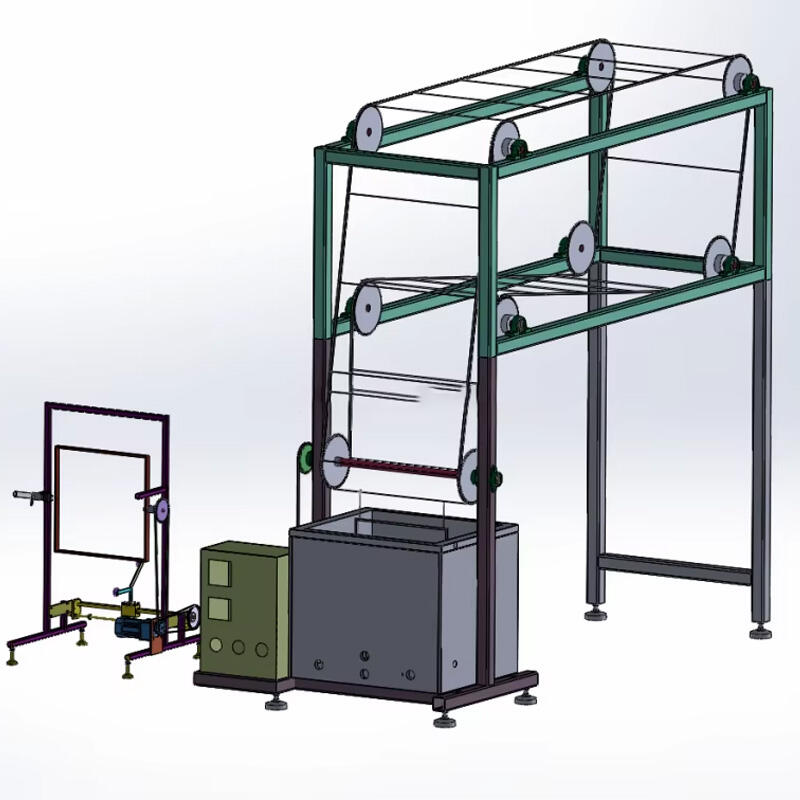

The electric candle making machine is a practical, efficient and Beautiful Candle Making Machine that can help you save time in the work of creating quality candles! Assembling and gluing are also avoided thereby shortening production time to less than half that of traditional methods with much manual work. On top, its inexpensive makes it blow little candle making companies identical. Candle manufacturing can be automated, and that's good as it saves operators time for one of the most crucial things in running a candle making business - they will have more time to actually work like marketing products.

If so, that is an entirely different story but remember this electric candle making machine the next time you are lighting a new wick. This unique machine has never been seen before and is the top of its technological setting for anyone new to making professional candles at home. While an operator is making a candle, it does much of the guesswork out for them by taking over more mundane tasks like temperature control and wax melting which then allows operators to dial in their specific color combinations or great any new fragrance profiles.

As much fun candlemaking may seem to be you can never compromise on safety, with electric candle making machine however all the work are done safely; you don't need fire as heat source which is associated the conventional way. Well have no fear, the machine has automatic shut-off, temperature control and even allows for you to keep your hands clean at all times with its automatic stirrers when working on the creation of candles if this is not your strong suit.

Using the electric candle making machine is an easy task and it does not require a lot of effort to make your own candles! Simply fill your machine with the correct amount of wax (and colors, if you so choose), set it to whatever temperature level meets your fancy and let all that wonderful-smelling goodness meld together in blissful melting harmony. The machine will achieve that mix of colors and scents flawlessly. Once it is solid, pour the wax into molds and allow to cool (do not disturb) until completely firm enough for removal from mold (also remember cut that wick so your candle does not look homemade!).

Service, Quality, and Support

These are an investment, and the best thing is that we will be getting after-sales services from a renowned manufacturer producing premium quality products. Hit up the company background, they are supported by probably some type warranty and replaceable parts on hand. Service The quality of service is a very important factor, from the advice and support to ensure that you are able to use it as best possible.

Three QC employees, eight Electric candle making machine quality control safety testing assure equipment meets standards safety uses.professional RD group comprising 5 members offer with custom solution 48 hours. Perfect machinery your candle-making business. We make equipment exactly requirements, just satisfy needs

Dongguan Yide Machinery Co.,Ltd expert manufacturing Electric candle making machine, main product wax melting tank, filling machine wick machine. factory covers area 2,500 square meters, standard semi automatic candle machine stock more 100 sets. fully automatic line always 2 sets stock. We a commitment offering best solutions engineering candle manufacturers around globe.

Electric candle making machine after-sales addressed one hour. customers appreciate experienced team foreign trade considerate service. also have highly skilled RD department which transform ideas working machine. production department responsible for step your production process until receive goods.

equipment constructed stainless steel food grade that corrosion-resistant anti-rust. It stands temperatures to certain point.order ensure efficacy precision ensure accuracy efficiency, stepper motor as well servo motor substituted normal motors. pump constructed stainless steel food grade type instead plastic iron.offer different sizes pumps 4L 6L Electric candle making machine 20L meet different filling range. touch screen PLC design allows you easily adjust parameters. example, filling ranges, speed which filling done as well temperature requirements more. There's wide assortment candle-related equipment available, not semi-automatic model as well fully-automatic one. machines upgraded terms detail, allowing more flexible stable.