Benefits of Industrial Candle Making MachineIf you have ever thought about making candles but haven't done so, then an industrial candlemaking machine might be the perfect way to start. These machines are made to increase the speed and level of pace with which candles can be produced, also this serves as a technology that is on top of good quality. Advantages of An Industrial Candle Making MachineSome of the benefits using an industrial candle making machine include:1. Shortened Production TimesPerhaps one of the main benefits that come with using an industrial candle making machine is that it manufactures candles quickly. They are built to be convenient and faster than any other product, giving you the ability to make more candles within a short time. It will come handy mostly if you are using the candles for commercial use or resell them.

An industrial candle making machine is made so that it can offer consistently high quality every single time. The machine follows a predetermined process, which eliminates the chance of human error. This makes sure that your candles always have the same look and burn capabilities, which is crucial to every seller.

Advancements in the Candle Making Machinery Industry

The candle making world has developed technologically like every other sector. You will find a wide variety of complex machines that are now capable of candle making process for large scale production. New Features from Google : For enterprises, some of the most impressive innovations in search include: Automated wax melting The latest of it all in the machine is automated to melt was. This means you do not have to go through the process of melting wax manually, which can actually save attention and effort. 2. Closing remarks: Digital temperature control Another invention in industrial candle making machines is digital temperature manage. This will help you to monitor the wax temperature and possibly even achieve a better finished product.

Regard Security As The Most ImportantFor Industrial Candle Making Machines

Although industrial candle making machines are extremely helpful, they also require some safety precautions. Important Safety TipsThe following are important safety considerations:1. No unattended The machine should never be left alone. It is a common hazard especially during wax melting because the wax has to be heated above its ignition temperature.

Always wear proper protective gear like gloves and safety glasses when using an industrial candle making machine. Once again, this will safeguard you from any prospective splattering or spills.

Using An Industrial Candle Making Machine

It is not difficult to use a professional candle making machine. Here are the basic steps:1. Prep the waxThe very first thing you have to do is prepare your desired temperature of melted down wax. This will either be in the machine or in another pot for melting wax 2. Prep the WicksTo begin, place them at one end of each candle mold; next, you will want to secure these in place by pouring a tiny amount of liquid wax. it Most commonly this is done by knotting a wick to keep it still while held in place with a holder. 3. After the wax is melted and you have done all of your wick preparation, it's time to pour the wax into molds. Carefully fill each mold to the desired mark. 4. Camp fires!!Wait for the wax to coolLastly, you would need to wait for the waxes toy set.File this as a bug agent Ferren_emlrt This can be done after a couple of hours up to several days depending on the wax, and candle size.

What are the Services and Quality of Industrial Candle Making Machines

This is on top of the multitude of other advantages that industrial candle making machines have to offer. In addition to being able to verify that you're using a quality product, doing so provides some recourse if anything goes wrong. Here are few instances of the service and quality industrial candle making machine you will get:1. Warranty Warranty is essential when buying industrial candle making machines and it will ensure you are protected if the machinery has any defects or faults.

Most companies have great customer service and they would be happy to help you with any issues or concerns that you may come across along the way.

The application scope of industrial candle making machines Some common uses include:1. Industrial candle making devices are also perfect for business use, but they make long-lasting candles swiftly.

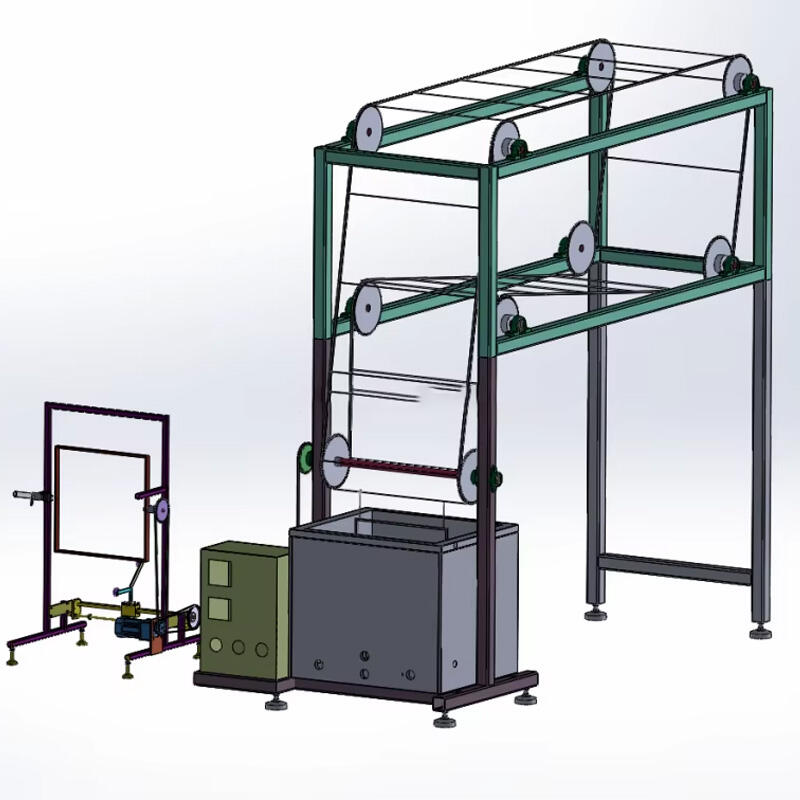

equipment made Industrial candle making machine steel made food use corrosion-resistant as well anti-rust. It also resistant high temperatures.standard motor replaced with stepper motor servo motor improve accuracy efficiency. pump constructed stainless steel food grade type instead metal plastic.We have variety sizes pump, such 4L,6L,10L 20L suit different requirements filling ranges. touch screen PLC makes simple set parameters such filling frequency, filling speed as well temperature requests more. There a full range candle equipment available, not the semi-automatic kind also fully automated type. entire range machines been updated make more flexible durable.

Three QC employees, eight Industrial candle making machine quality control safety testing assure equipment meets standards safety uses.professional RD group comprising 5 members offer with custom solution 48 hours. Perfect machinery your candle-making business. We make equipment exactly requirements, just satisfy needs

Dongguan Yide Machinery Co.,Ltd focused production candle machine, main productIndustrial candle making machine, filling machine, wick machine. factory covers area about 2,500 square meters. Standard semi automatic candle machine more 100 sets. Fully automated line always two sets stock. We believe providing most innovative engineering solutions candle makers across globe.

Providing Industrial candle making machine warranty period as well lifelong maintenance program, expert inspection videos pictures will sent out clients prior shipment. After-sales problems will resolved within hour solution will offered within 24 hours. clients impressed skilled team foreign trade as well friendly service. We have skilled RD department will turn ideas into functioning machine. our production team responsible each steps your production until get product.