If you are out on the prowl for a new exciting hobby where you get to explore your creative side, then this is it,crochet.ERROR-FREE CROCHETING. Are you an entrepreneur wanting to broaden your repertoire and attract additional customers,... It is exactly what the doctor ordered. Introducing to you- The candle making machine! Without further delay let's get to know the candle maker machine along with its numerous benefits such as advanced features, ease of use, how it works step-by-step instructions and the kind of candles you can expect from it that are superior in quality and versatility.

Benefits of Using Apparatus to Make Candle

There are a number of reasons to consider investing in the purchase of candle making machine namely For one, it allows you to make a large number of candles at an affordable rate which ends up in saving as money over the long run. It also ensures that you have a consistent candle every time, leaving each and very nauseous of the results fairly high quality. Thirdly, it is an excellent place to begin a candle-making business of your own since the unique and handmade candles market grows larger all time.

Candle making is an art form that has been around for centuries, and the candle making machine gives new life to this age-old craft by adding innovation. It allows you to create complex designs and patterns that would be very difficult to do by hand. The best part is it allows for playing with a variety of materials - wax types and scents as well, also you can have objects in the candles that definitely gives creativity point to the candle maker making endless possibilities.

Safety and the ease of use have been paramount in designing a candle making machines for all skill level users. This machine does not require expert skills — simply plug it in, add your wax and power on. With an inclination protection feature and automatic temperature control, the device will automatically shutoff in case over-heating occurs to protect you from accidents. Moreover, it is non-toxic and does not give off dangerous fumes or chemical substances leading to a more secure environment while looking out for your well-being.

The candle making process is straightforward, even when using a simple candlemaking machine. These are the detailed step-by-step instructions on how to create a candle that actually lights up;

Depending on the type of wax you select, whether it be soy or Para-soy blend, begin by melting your wax in a double boiler process or use microwave.

Pick a fragrance or some essential oils to add wonderful scents into your candles!

Place the melted wax in a container and pour it into your machine reservoir.

Attach the molds with their wicks in place. The machine is capable of filling the molds automatically with wax and chilling out this setup could help in making different shapes candles for you.

The unique quality of a candle making machine lies in its capacity to continually produce high-end candles. This machine is designed to deliver perfect looking and smelling items. The machine takes care of everything — No more uneven or lumpy candles, just perfect precision and perfection in candle making with the right expertise.

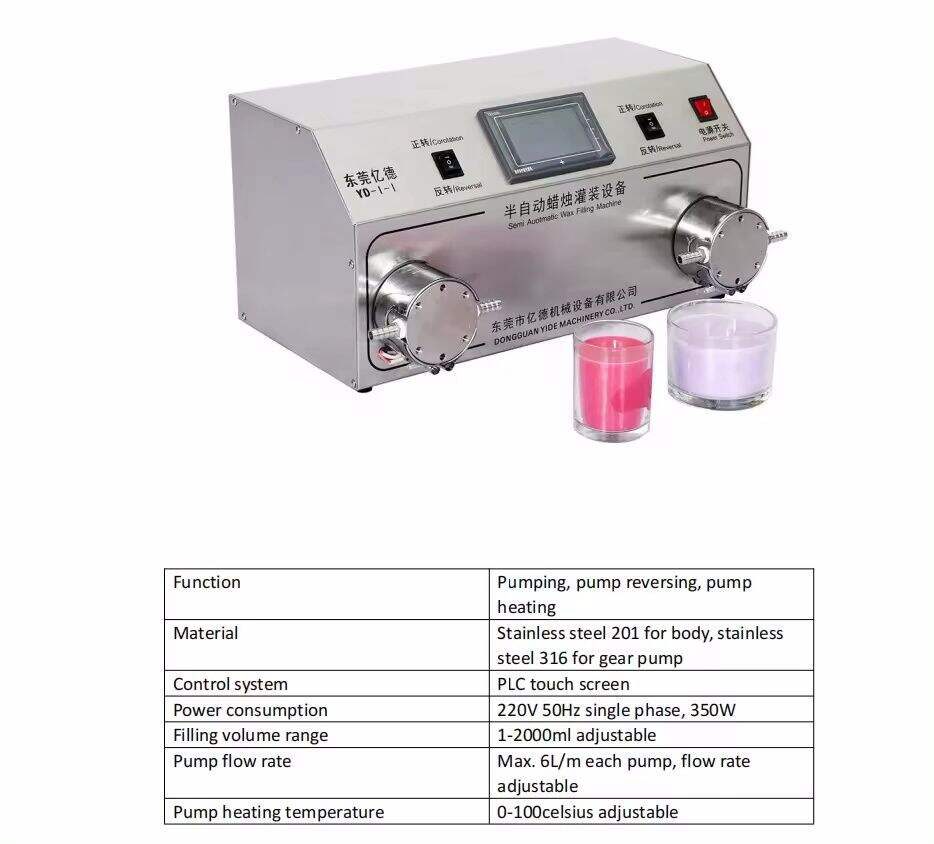

Candle machine maker constructed food-grade stainless steel 304. anticorrosion, antirust has high temperature resistance.order ensure effectiveness accuracy, stepper motor servo motor used instead regular motors. And pump made food grade stainless steel 316 instead iron plastic.There variety sizes pumps, such 20L 4L/6L/10L meet different ranges filling. touch screen PLC makes easy set parameters,such as filling range,filling speed temperatures, filling speed more. There full selection candle equipment available that not limited the semi-automatic type also fully-automatic type. machines upgraded regard details, allowing greater flexibility more stability.

With 1-year warranty lifetime maintenance service. professional inspection video pictures will sent clients Candle machine maker shipment. After-sales problems resolved within 1 hour, solution will provided within 24 hours. customers appreciate experienced team foreign trade as well professional service. Also have professional RD department which transform ideas actual machine. Production department responsible each stage production point receive goods.

Three QC employees, eight stages quality control, safety tests ensure machine compliance guidelines safety use.We a group five professionals who offer you custom solution just 48 hours. ideal equipment candle manufacturing business. We Candle machine maker build machine meet requirements.

Dongguan Yide Machinery Co.,Ltd Candle machine maker production candle machine, main product wax melting tank, filling machine wick machine. factory cover area approximately 2,500 square metres, standard semi-automatic candle machine available more 100 sets, fully automatic line always 2 sets stock. We committed providing most innovative engineering solutions candle manufacturers around world.