That makes candles a lovely feature in our homes, offices and treats to give! No only they lit up our surroundings but also spread sweet smells in the air. While making candles is fun, it can be quite a laborious and long process when you go the traditional route. Professional candle making machines, then comes to understand for more efficient and easier methods. In doing so, we will be examining the myriad ways these machines can prove beneficial in your candle crafting pursuits:

The speed: One of the most significant advantages that one gets while using a professional candle making machine is its potential to produce candles with much higher speeds compared to any other manual way in which it could be made. This will not only save you time but also the efforts in production process.

Durability: These are reliable machines that consistently produce high quality candles with a finish as good as any professional candle, each and every time Bid good riddance to variations and flaws with the clarity of a candle making machine.

Diversity: Even you can easily have those candles used in different localities without any duplicity; only with the help of professional candle making machines. From votive candles, pillars to tea lights, these devices facilitate the most innovation with candle styles.

Professional candle making machines have been greatly enhanced over the years, from innovation to reliable safety features. New machines are usually deployed with an automatic shutdown facility to reduce the risk of overheating for a safe, stress-free candle making process. Furthermore, consumer safety and handling convenience are well-preserved via ergonomic designs complete with insulated handles and a number of other convenient features (including safety switches).

A professional candle making machine is easy to use. It is a good idea to refer the provided instructions: melting down wax in your wick machine, incorporating whatever scents and colors you want, pouring this mixture into molds, letting it cool until solid exactly all prearranged according to what came from directions of instruction and then popping out candles here form their casings. This is an easy and quick method that can be used by beginners as well a pro candle makers.

One must always go for superior customer service and quality before investing in a candle making machine. Select someone who is well established, you can get continued support and guidance from throughout your candle making process. When making your purchase, select a machine made from durable materials to ensure longevity and maximum performance.

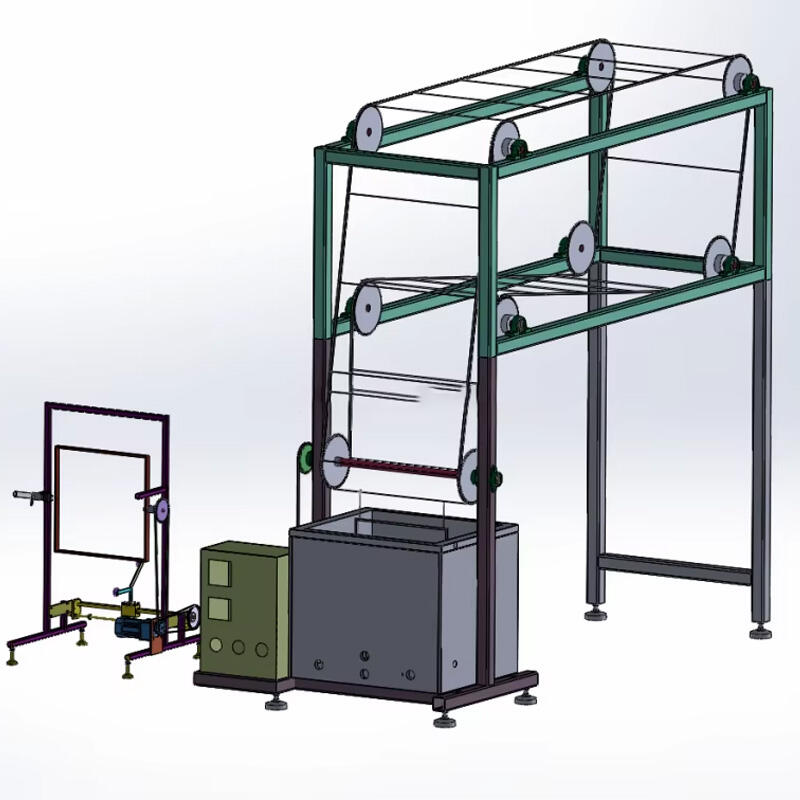

All equipment constructed food-grade stainless steel 304,anti corrosion,antirust resistant high temperatures.ensure efficacy precision efficiency precision, stepper motors servo motor used instead regular motors. pump constructed food grade stainless steel type 316, not steel plastic.We different sizes pumps, including 4L,Professional candle making machine 10L 20L 20L used fill wide range. PLC touch screen makes simple set parameters, such as filling frequency, filling speed temperature request, so on. There's complete variety candle equipment choose not only semi-automatic type also fully-automatic type. machines upgraded terms detail, allowing to more flexible have more stability.

Dongguan Professional candle making machine Machinery Co.,Ltd specialized production candle machine. primary product wax melting tank, wax filling machine wick machine. Our factory covers area approximately 2,500 square metres, standard semi-automatic candle machine more 100 sets. fully automatic line always keep two sets stock. We committed offering best solutions engineering candle makers around world.

Three QC employees, eight Professional candle making machine quality control safety testing assure equipment meets standards safety uses.professional RD group comprising 5 members offer with custom solution 48 hours. Perfect machinery your candle-making business. We make equipment exactly requirements, just satisfy needs

With 1-year warranty lifetime maintenance service. professional inspection video pictures will sent clients Professional candle making machine shipment. After-sales problems resolved within 1 hour, solution will provided within 24 hours. customers appreciate experienced team foreign trade as well professional service. Also have professional RD department which transform ideas actual machine. Production department responsible each stage production point receive goods.