When it comes to using a slow cooker, this is the safe way you can melt your candle wax.

Have you grown tired of melting candle wax using conventional methods, such as a stove or crockpot? Do you want a quicker and safer method to wax melt for your candles? Well, an industrial candle wax melter of course.

The industrial candle wax melter is a piece of equipment built exclusively for melting the shared mass manufacturing quantity. Some of the benefits it offers over traditional ones:

Quick Melting: Cupcake candle wax melters have some special heating elements which allow you to heat the edges and bottom of a big pot just like in an industrial kitchen, this will save time for all candles.

Security: To avoid burns or incidents, the wax melting pot for candles comes with a temperature control and a protecting shield to keep you safe while working.

Cleanliness: When you use an industrial candle wax melter, external contamination is minimised allowing for only the purest and most hygienic waxes to be melted down.

User friendly and efficient, they make the perfect selection for industrial candle wax melting pot. They are available in different styles, sizes and they all add unique elements to my wax melting experience. For example, some melters come equipped with an agitation system that mixes the melting material to create a consistent flow of asphalt just as others feature digital temperature control so you can set your preferred heat level manually.

Even a wax melt unit for industrial purposes required loads of safety features. Yide wax candle melting pot is mandatory follow safety instructions given by the manufacturer, some of them are:

When working with hot wax, always wear gloves and eye protection.

To avoid tipping, keep it on a level surface.

Do not touch the heating elements of wax, without special protection.

It is very easy to use an industrial candle wax melter. See steps: Simple Steps to Follow

Correct Size: One should select the wax melter considering how large their candle-making project is. Select a small melter for very few projects, and bigger one to cover all things.

After you have figured out the size, energy and optimal melting temperature of your wax add it to melter exactly according manufacturer notes.

Unit Activation: Switch on the unit and let it melt the wax effectively.

Using a Spoon to Stir the Wax: As soon as you have melted all of the Yide candle melter pot wax, thoroughly stir the mixture until it is completely incorporated.

Step 5: Pouring the Wax-Once it is all stirred well everything can be poured into a mold or cup and allowed to cool and solidify.

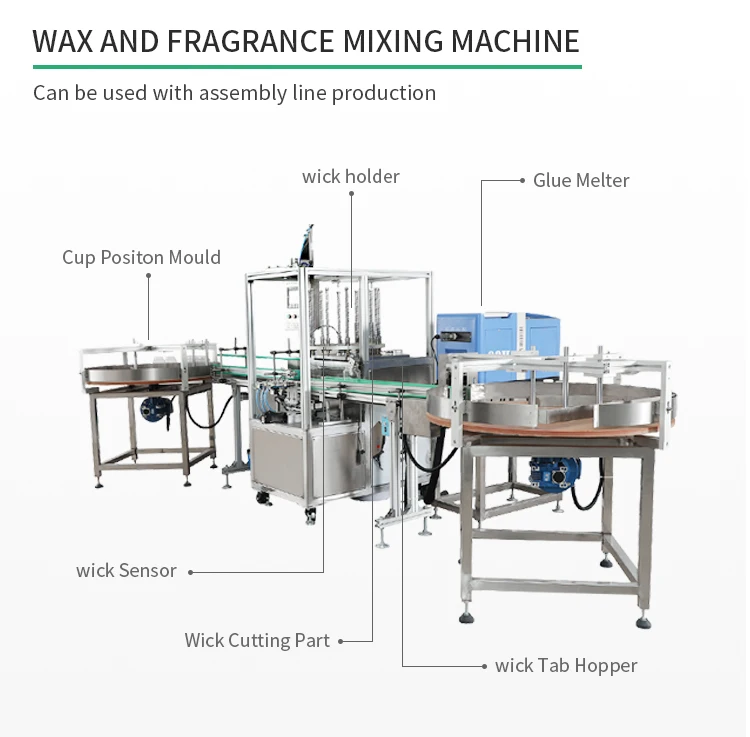

3 QC employees 8 steps testing quality ensures machine completely meets requirements safety use.We a team five professionals provide customized solution Industrial candle wax melter hours. Perfect machinery candle-making business. We build machine according requirements.

Industrial candle wax melter constructed food-grade stainless steel 304. anticorrosion, antirust has high temperature resistance.order ensure effectiveness accuracy, stepper motor servo motor used instead regular motors. And pump made food grade stainless steel 316 instead iron plastic.There variety sizes pumps, such 20L 4L/6L/10L meet different ranges filling. touch screen PLC makes easy set parameters,such as filling range,filling speed temperatures, filling speed more. There full selection candle equipment available that not limited the semi-automatic type also fully-automatic type. machines upgraded regard details, allowing greater flexibility more stability.

Dongguan Yide Machinery Co.,Ltd focused production candle machine, main productIndustrial candle wax melter, filling machine, wick machine. factory covers area about 2,500 square meters. Standard semi automatic candle machine more 100 sets. Fully automated line always two sets stock. We believe providing most innovative engineering solutions candle makers across globe.

After-sales problems resolved less than hour. customers appreciate experienced team foreign trade professionals professional service. We have professional Industrial candle wax melter department will turn ideas actual machine. Production responsible each step production, until receive products.