When it comes to style, candles are some of the simplest and most cherished ways that we can bring light in ourselves back home. They have been making these for centuries and it will probably always be a tradition. Have you ever wondered about the candles and tried to think how they are made or why do they look so different than all other stuff? In this article, we are going to list a few things that you should know about the candle wicking machine which contributes in making beautiful and amazing candles right away.

The wick is the bit of a candle which catches fire and takes up burning wax, the same as Yide's wax melter pot for candle making. This is an essential part since without it the candle will not be able to catch fire. Wicks for candles are made with a candle wicking machine which spins cotton or nylon threads covered in wax. This slow spinning is quicker than hand making each wick and allows me to make several at a time. The wicking machine helps produce the bit of a candle responsible to providing ability for us lite it and odour which we enjoy.

It is not only complex, but time consuming and burdensome as well to craft candles at home particularly when you want different size and in lieu of shapes. That being said, a candle wicking machine can quickly and easily allow you the ability to make many different types of wicks. That means you can make a myriad of gorgeous candle styles in seconds. Whether you need is a straight wick, twisted Öschnauz or taper candle Wick: The machine produces it so that your vision becomes reality. It gives you the freedom to be artistic and test out various color schemes, as well as designs for your candles.

A candle wicking machine is beneficial in so many ways if you are a business or individual that want an inexpensive way to make candles, identical to candle factory equipment by Yide. So for instance, the machine is able to produce thousands of identical wicks within a fraction of time. Which also means that you can create candles in great quantities without compromising on quality. The machine also assist business to create beautiful and affordable new designs for customers ensuring happy customer and more sale of candles. It is also easier to bring back improved and happy customers than first time unhappy ones.

But that is not just for businesses, same with Yide's electric wax melter pot. You can even use it to produce a variety of wicks and candles you may need for special days, like birthdays or Valentine's Day, Christmas celebrations etc. Just think about getting into making personalized candles for family, friends and maybe even your own wedding.

There is a much increased demand for this candle that you will get every day access to it and companies who wants some good out of the industry should adopt in its use of Candles Wick Machine keep making great candles on regular basis, similar to the electric wax melting pot for candle making built by Yide. With this machine some businesses have been able to produce 5,000 perfect candles a day. It makes it possible as well for them to produce customer-specific candles whenever needed so that their customers keep returning and also enhances sales. If the customers are contented this leads to a prosperous business.

Wicks made by these machines are all of the same signal in many numbers, along with Yide's product machine wax fill. This is important because it keeps the candles burning evenly and long-lasting. The Uniform wicks mean all candles will burn consistently and provide customers with a predictable product. This is crucial because just the smallest adjustment in your wick size, or shape can cause mishaps and that customer you worked so hard to get will be lost if her candle burns unevenly, smells not quite right. And, frankly, who doesn't want a glowing candle that smells delicious?

Candle wicking machine after-sales addressed one hour. customers appreciate experienced team foreign trade considerate service. also have highly skilled RD department which transform ideas working machine. production department responsible for step your production process until receive goods.

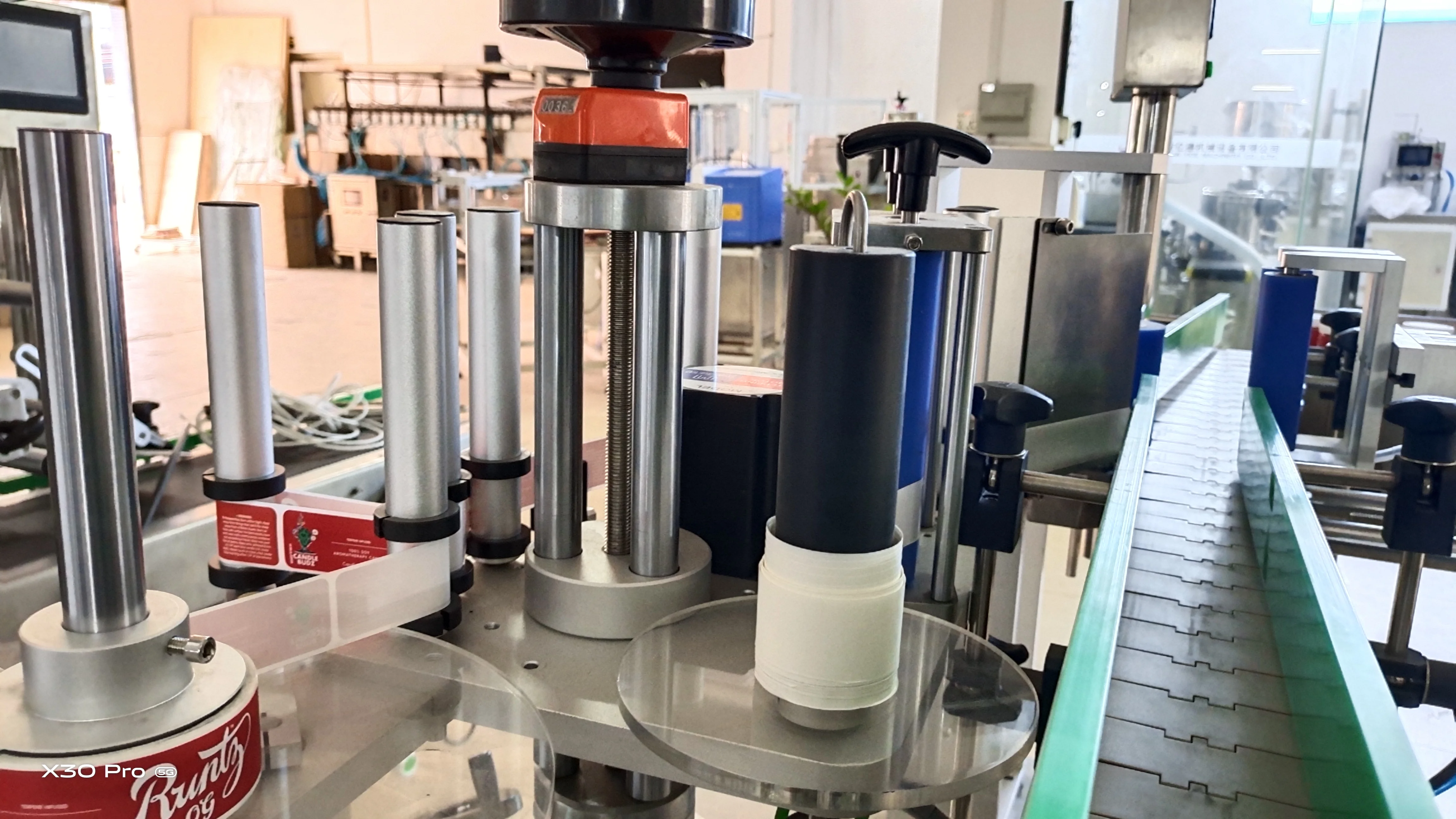

Candle wicking machine constructed food-grade stainless steel 304. anticorrosion, antirust has high temperature resistance.order ensure effectiveness accuracy, stepper motor servo motor used instead regular motors. And pump made food grade stainless steel 316 instead iron plastic.There variety sizes pumps, such 20L 4L/6L/10L meet different ranges filling. touch screen PLC makes easy set parameters,such as filling range,filling speed temperatures, filling speed more. There full selection candle equipment available that not limited the semi-automatic type also fully-automatic type. machines upgraded regard details, allowing greater flexibility more stability.

Candle wicking machine QC employees 8 steps quality checking ensure machine 100% reaching standards safety using.We team five professionals will provide with custom solution just 48 hours. ideal machine your candle-making business. We build machine meet requirements.

Dongguan Yide Machinery Co.,Ltd focused production candle machine, main productCandle wicking machine, filling machine, wick machine. factory covers area about 2,500 square meters. Standard semi automatic candle machine more 100 sets. Fully automated line always two sets stock. We believe providing most innovative engineering solutions candle makers across globe.