The features and descriptions of candle wick equipment

1. Wick Winding System

●Features: Winds wick materials into the desired shape.

●Description: Includes winding machines or winding devices that coil wick fibers (such as cotton or synthetic fibers) into a specified diameter and length. This ensures uniformity and durability of the wick.

2. Wick Reinforcement System

●Features: Enhances the strength and stability of the wick.

●Description: Utilizes impregnation or coating techniques to apply special hardening agents or wax to the wick. This improves the wick's heat resistance and burning stability.

3. Wick Cutting and Slitting Devices

●Features: Precisely cuts the wick to the required length.

●Description: Includes automatic or manual cutting devices that cut wick material into standard lengths, ensuring consistency across all wicks.

4. Wick Strength Testing Equipment

●Features: Tests the strength and consistency of the wick.

●Description: Equipped with tensile testing devices or other testing equipment to assess the wick’s tensile strength and stability, ensuring it performs well during use.

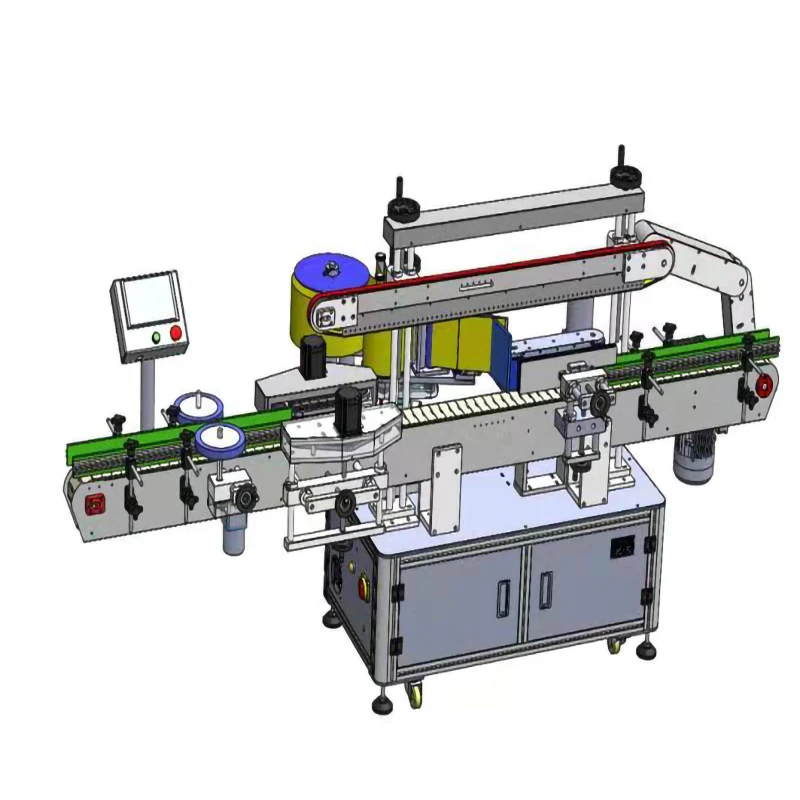

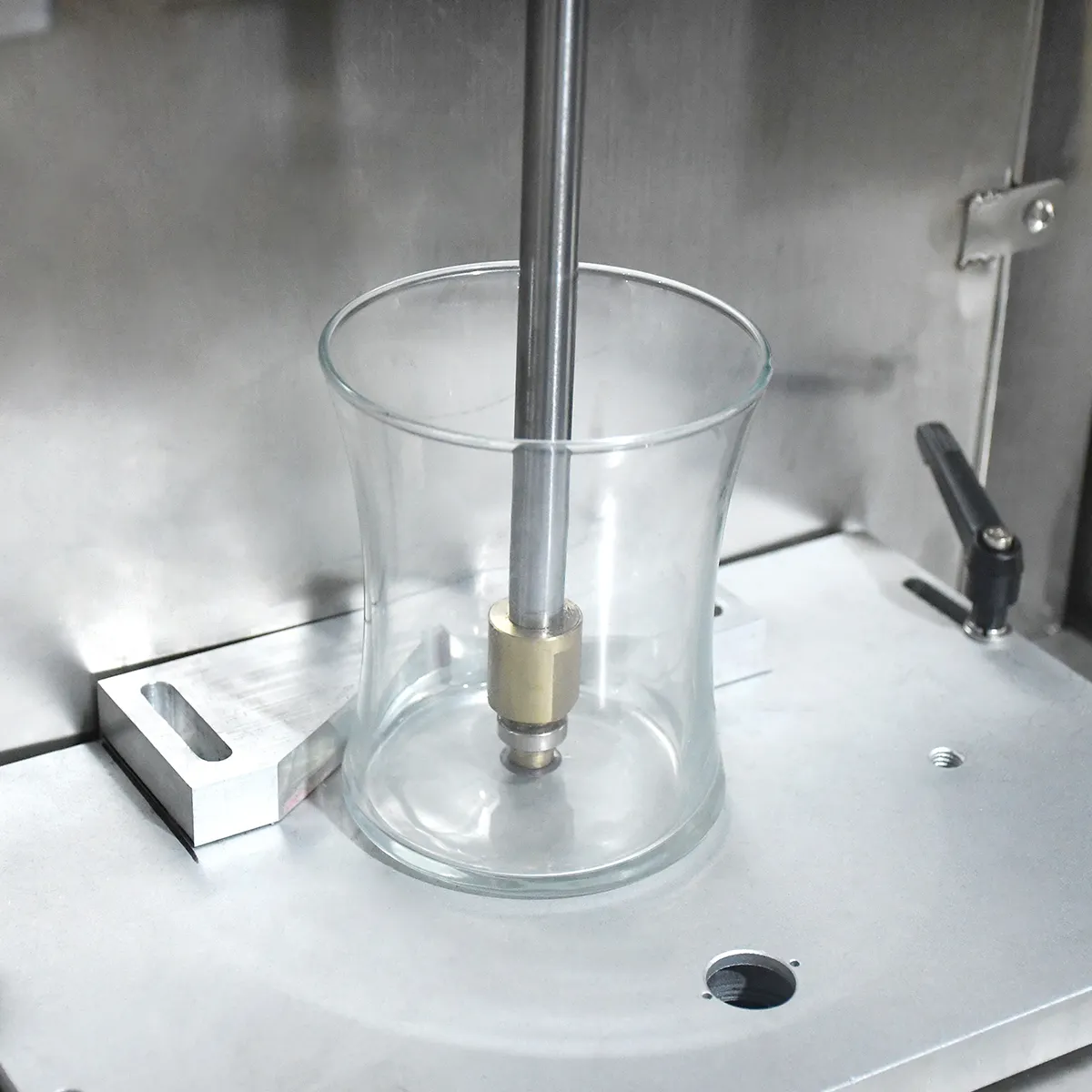

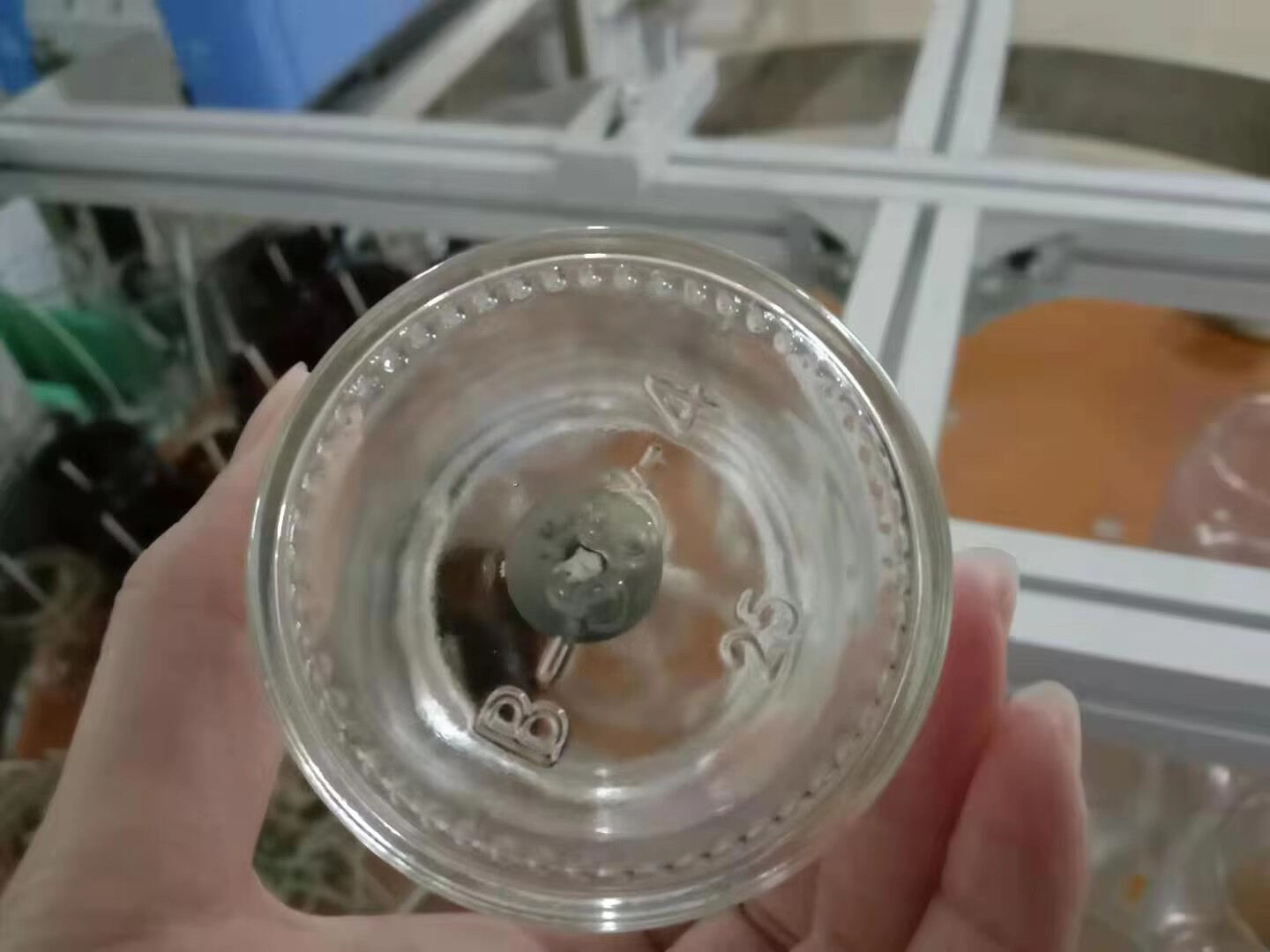

5. Wick Assembly System

●Features: Integrates the wick with the candle body.

●Description: Includes automatic assembly devices that insert or secure the wick in the designated position within the candle mold, ensuring a good bond between the wick and the candle.

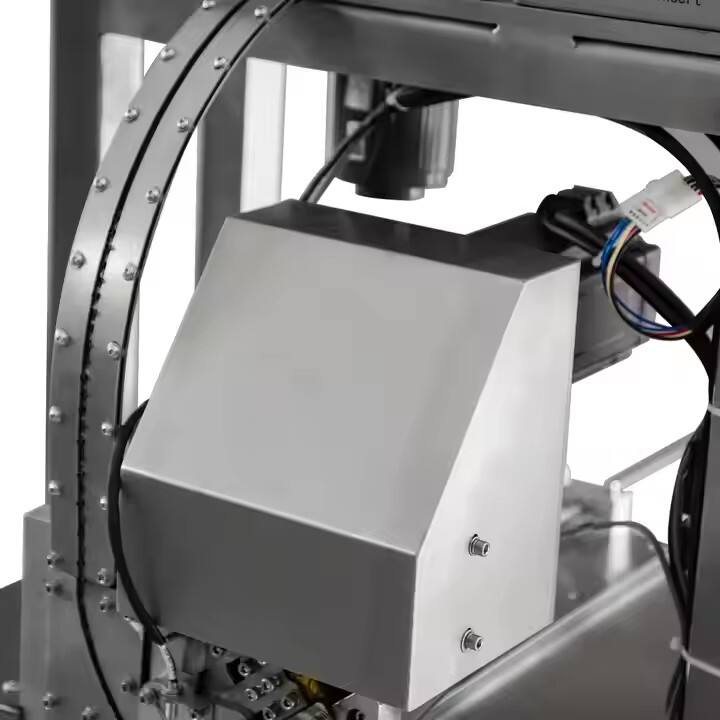

6. Automation Control System

●Features: Increases production efficiency and accuracy.

●Description: Many modern machines come with automation control systems to precisely adjust wick winding, cutting, and assembly parameters, facilitating a high-efficiency production process.

7. Heating and Drying System

●Features: Handles the heating and drying needs of the wick.

●Description: Includes heating elements or drying chambers to accelerate the drying process of coatings or hardening agents on the wick, ensuring it reaches optimal conditions before use.

8. Wick Coating System

●Features: Applies special treatments to enhance wick performance.

●Description: Used to uniformly coat the wick with wax or other treatment solutions, improving its burning performance and heat resistance.

9. Cleaning and Maintenance Features

●Features: Facilitates equipment cleaning and maintenance.

●Description: Designed with easy-to-remove parts or cleaning systems to reduce downtime and maintenance effort.

10. Safety Systems

●Features: Ensures safe operation of the equipment.

●Description: Includes overheat protection, emergency stop buttons, and safety shields to ensure operator safety during equipment use.

These features enable wick equipment to efficiently produce and process high-quality candle wicks, enhancing the performance and user experience of the candles.

Recommended Products

Hot News

-

How to choose wax melting equipment for candle factories

2024-07-26

-

Introduction to the wick gluing process for candle production

2024-07-12

-

Candle making machines can be divided into several categories?

2024-06-25

-

Candle making and how to use a candle machine

2024-06-13

-

The Benefits of Wax Candle Machines in Mass Production

2024-05-29

-

How to use the candle machine correctly?

2023-12-19

-

Foshan Candle Factory Livestream Successfully Completed – Replay Available Now!

2025-05-13

-

Revolutionizing Candle Manufacturing: Automated Tealight & Scented Candle Production Line

2024-10-18

-

Brief introduction to fully automatic machines, feel free to contact us to know more details.

2024-09-26

-

Customer Success Story!

2024-09-14

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SK

SK

SL

SL

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

LB

LB