Best Options, Considerations for Setup & Maintenance Tips of Round Cotton Wick Making Machine

Cotton wicks are invaluable across many environments, from creating the perfect ambiance with a household candle to meeting specific demands in industrial applications. Even after the digitalization of everything in this world, but still we can see such round cotton wick machines running efficiently and producing or you may call whatever they do. Therefore, in this article we will cover the best round cotton wick making machines you can get for a small business, what to look at when buying it and then give an exhaustive guide on how to make a continuous supply of the product using such machine all year with proper maintenance tips that makes your purchase worthwhile!

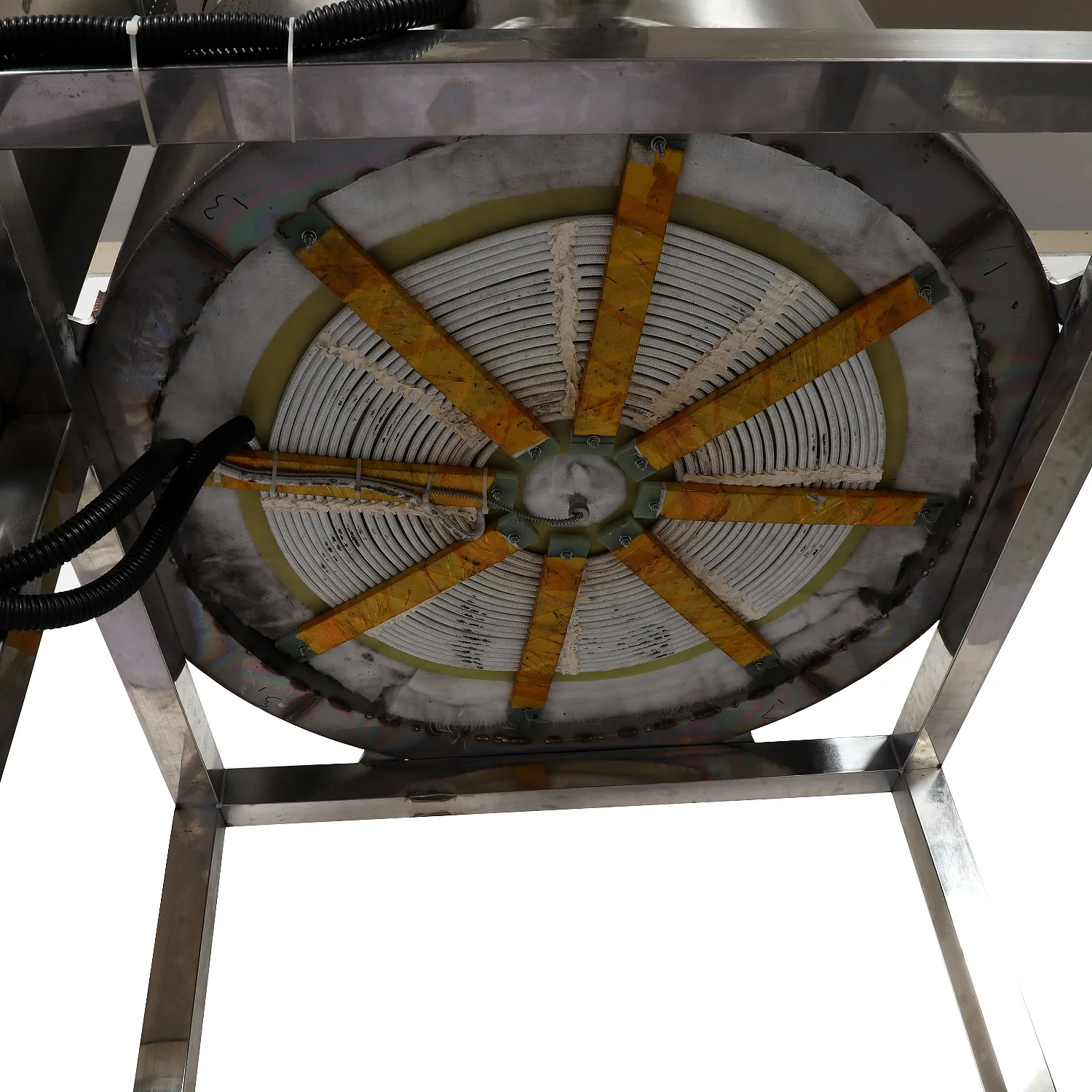

The best Round Cotton Wick Making are providing a balance of speed, precision and customization ability. One great option is the Semi-Automatic Round Cotton Wick Making Machine This machine has unique out capabilities of Round Cotton wicks which are available in assorted sizes It has a wick sizing control and an automatic wicking mechanism that ensures reliable cotton in-take by the machine. It is also a small unit that can assist in easy handling and storage

One more worthy option is the Automatic Round Cotton Wick Making Machine. It is the best at producing cotton wicks of round dishes, all with automatic and high speed operation this device reaches its peak performance. This computerized model effortlessly creates consistent wick lengths and lessens the need for human control. Designed thoughtfully for simple assembly and disassembly, which increases usability.

Three the maximum amount smaller businesses, particularly for a period of investment in their rounds cotton wick making machine is primarily capital. Hence, the best-in-class machines for small businesses have to provide a combination of cost-effectiveness and performance capabilities including speed, accuracy range of options because they would be catering to various print shops

Manual Round Cotton Wicks Making Machine is one such option. It is simple and low-cost machine to consider in small plants. It also offers 3 different wick sizes and a ruler to get the exact size for your wicks making sure you don't oversize them. It is small in size to ease handling and storage

Semi-Automatic Round Cotton Wick Making Machine:This is also a fine option for the small businesses with average production levels. The machine is good at producing wick in various sizes attached with a wick feeder for ease of cotton feeding to the machine. It has a small and compact design making it easy to store whenever not in use

Things to keep in mind while buying round cotton wick making machine

Before purchasing round cotton wick making machine, some important points should be taken into consideration

Production Speed/Volumes: You need to make sure you can achieve necessary production output in a reasonable amount of time

Precision and Accuracy- Make sure the machine is capable of creating a consistent wick size uniformly across all produced

Ornamentation: Choose a machine capable to produce wicks in different shapes and sizes

Conclusion: Ensure that the Unit is Easy to Use and Comes with a Good User Manual

Support: Is it hard to maintain, are parts readily available for replacing

Round Cotton Wicks Making Machine Installation Operation Guide

Once setting up the Yide fully automatic round cotton wick making machine. Also with the machine should come a manual and instruction to assist in setting up efficiently. Below is a short guide to help you out

Preparation: Locate the sewing machine on an even space and remove power supply.

Thread the cotton reels through feeding mechanism to maintain a continuous flow of cotten being fed into the machine

Choose the exact size of your wick and put in a sizing tool

The Yide long cotton wick machine can be started of erection and a large numbers if round cotton wicks cane be produced in no time

A round cotton wick making machine requires regular maintenance to maintain high operational efficacy. First of all let's check it out for some Useful Maintenance Tips and Troubleshooting Points

Be sure to lubricate it or some kind of substance in the machine, so that you do not wear out over time

Inspect common wear-and-tear parts regularly, and change any that are broken or deteriorated

Regular cleaning of the machine to prevent dust or debris from solidifying over time plugin

If parts do not work, refer to the user manual or get in touch with your producer for troubleshooting

Ultimately, Yide cotton wick making machine modern production has created the ability to employ advanced round cotton wick making machines that are both efficient and highly reliable Considering several machines are available in the market, is essential to remember those discussed issues before buying one Make sure you keep track of your car, calling in the right servicing it needs and to trouble shoot problems before they get out of hand.

Dongguan Yide Machinery Co.,Ltd expert manufacturing Round cotton wick making machine, main product wax melting tank, filling machine wick machine. factory covers area 2,500 square meters, standard semi automatic candle machine stock more 100 sets. fully automatic line always 2 sets stock. We a commitment offering best solutions engineering candle manufacturers around globe.

equipment manufactured food grade stainless steel which anti-corrosion, anti-rust resistant high temperatures.motor normal model replaced an servo stepper motor greater accuracy efficiency. Additionally, pump constructed food grade stainless steel instead iron plastic.We offer different sizes of pumps, including 4L,6L 10L Round cotton wick making machine and 20L meet different filling range. touch screen PLC allows easy adjustmentparameters. instance filling ranges, speed which filling done temperature requirement lot more. full range candle equipment that can selected, just semi automatic also fully automated type. machine updated detail, more adaptable more stability.

Three Round cotton wick making machine employees 8 steps quality checks ensure machine 100% reaching standards safety using.With experienced RD team comprising 5 members offer custom solution 48 hours. perfect machine your candle-making business. We able build machine precisely your specifications, just meet requirements

Round cotton wick making machine after-sales addressed one hour. customers appreciate experienced team foreign trade considerate service. also have highly skilled RD department which transform ideas working machine. production department responsible for step your production process until receive goods.