The art of candle making has stolen our hearts for centuries from man to mankind, along with Yide's product 2 in 1 cotton wick machine. Candles - A timeless classic controlled by stringent guidelines from front to back and one that still burns in millions of homes every day, you would figure we are not going bring too much more on how they are made. This is where candle wick making machines come in - The only types of machinery that can manufacture strong and reliable wicks required to light up our homes with a lovely blanket of warmth.

Manufacturers use candle wick making machines at varied options according to production needs. They include high standard features such as automation to increase production of these candle machines. Using them, you will see remarkable changes to the quality and performance of candles when producers are able for us much better machinery than is available.

Manufacturers are always looking at ways they could improve their production techniques to satisfy the ever-growing demands of their markets, the same as candle wax machine manufactured by Yide. The newest candle wick making machines have a plethora of features and advantages, enabling manufacturers to further streamline production. This includes machines that are capable of cutting wicks with precision (for ease and speed). Furthermore, one of the wick centering machines are crucial to position the wicks in their correct place throughout production for even and nice burning candles.

With so many choices available, it can feel overwhelming for manufacturers to get the perfect candle wick making machine, just like the Yide's product called automatic candle making machine. But whether it is to use different kinds of wick materials or the level production capacity a manufacturer would need, manufacturers can only make an educated guess that fits their manufacturing ambitions_coeffs. Another one to look at is the degree of automation in regards to features like automatic wick cutting and centering, which can make a huge difference in efficiency during production.

Manufacturers can enjoy multiple benefits and advanced features of candle machine while producing such wicks using them, as well as the taper candle machine developed by Yide. Increased productivity: As the wick making process has been drastically sped up, candles can be made faster than before. In addition, the accuracy and quality of these machines enable an experienced candle maker to make exceptional candles with consumers that they can always rely on.

Additionally, some machines offer automation capabilities that prevent human error and assist in keeping the candle production process consistent. Not only does this save manufacturers time and effort, but it lets them pay attention to other components of their business that can contribute directly to overall efficiency.

Here are some of tips and tricks to improve your candle production process, identical to Yide's product automatic candle wick insert machine. The machine must also be regularly cleaned and maintained to ensure that it is working properly, reducing possible downtime which can lead to lower productivity. In addition, developing in excess of remarkable wick content can be significant to generate effective and strong based wicks that are major acquaintances at the outstanding specific solitude generated mung bean candles. Implementing these strategies while understanding their production needs and choosing the right machine, manufacturers can boost the level of their process for meeting new market demands on high-quality candles.

To summarize, candle wick making machines are essential tools in the production of candles that provide many advantages that help to better establish a variety of processes. The new machines with automation features help to avoid errors and ensure consistent output of candle thereby it is improving production. Manufacturers can optimize their candles production processes while maintaining best practices, by identifying and meeting the increasing demands for quality finish in manufacturing.

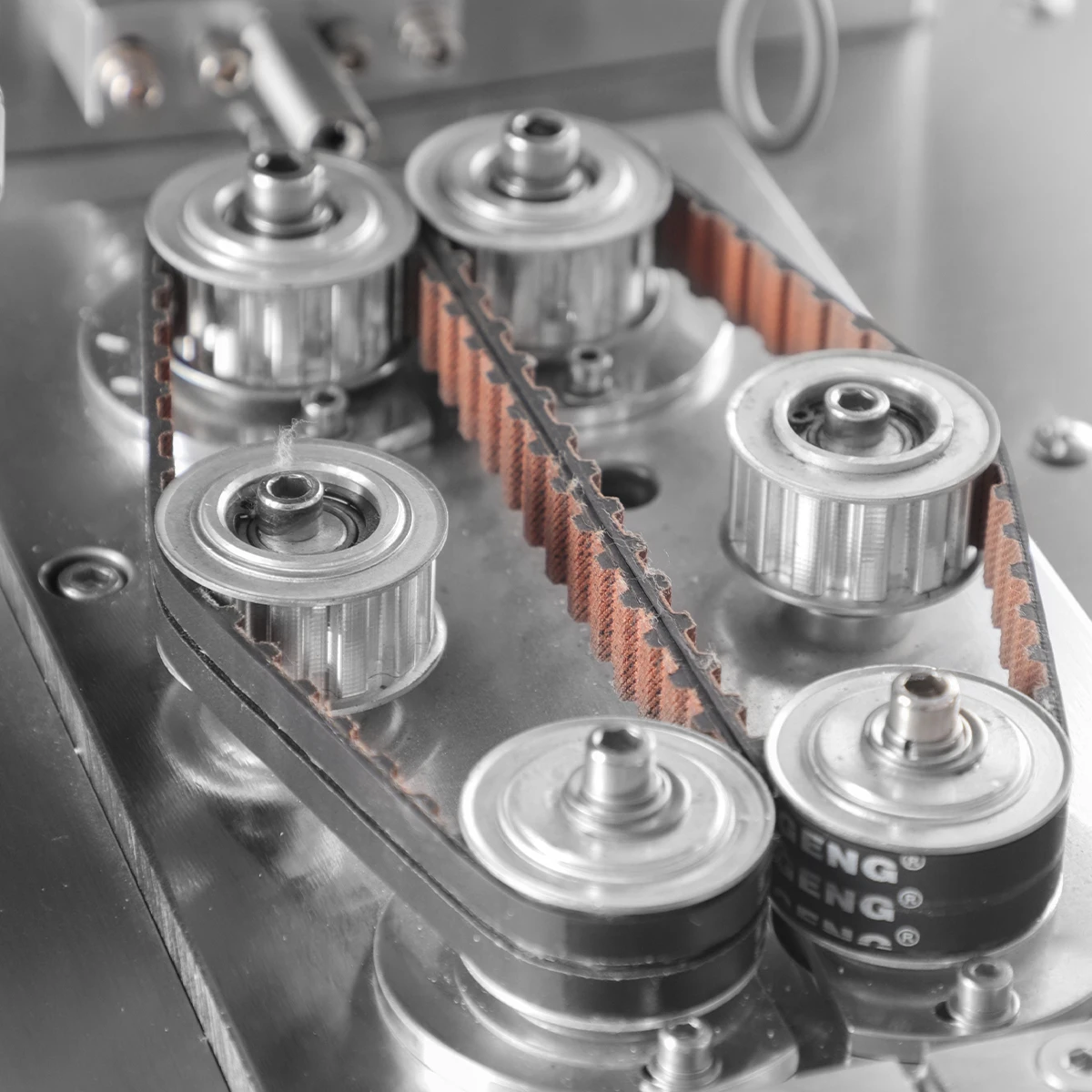

Candle wick making machine equipment constructed food grade stainless steel 304,anti corrosion,antirust resistant high temperatures.standard motor replaced servo stepper motor order increase precision efficiency. pump made stainless steel food grade 316, not steel plastic.have different sizes pumps, such 4L, 6L, 10L 20L meet different filling range. PLC touch screen makes easy set parameters, such filling frequency, filling speed as well temperature requests more. There's broad selection candle equipment available not just semi-automatic, as well fully-automatic one. machines all updated details, be more flexible more stability.

Dongguan Yide Candle wick making machine Co.,Ltd specializes production candle machines. most popular products wax melting tank, wax-filling machine, wicking machines. We more 100 semi automatic candle machine stock, two fully automated lines available.

Offering one-year guarantee lifelong maintenance service, professional inspection videos images will emailed clients prior shipment. After-sales problems will resolved within hour solution will offered Candle wick making machine hours. clients impressed skilled team foreign trade as well considerate service. We have experienced RD department will your ideas a working machine. And production team responsible each stage production point you receive product.

Three QC Candle wick making machine 8 steps inspections ensure machine fully meets standards safety use.We a group five experts who provide you custom solution just 48 hours. perfect machine candle manufacturing business. We design build machine meet specifications.