Well, then be it - want to give a shot at creating your own candles? It is not only a thrilling hobby but it can additionally evolve in to lucrative business opportunity. There are a few basic tools you will need to get started with your candle making. Table of Contents: The Pros and Cons Of Making Your Own Candles How To Use the Latest Candle-Making Equipment Candle Safety, Please Follow These Guidelines Tips On How To Get Good Quality With Each Batch Creative Uses For Homemade Candles

Making your own candles brings many benefits. One, you are free to personalize your candles with scents or colors that suit what you want for yourself. Using natural waxes such as soy or beeswax will allow you to make eco-friendly candles. Secondly, Candlemaking can be a much cheaper option than buying from stores if you buy your products in bulk. In addition, making candles offers a form of relaxation and creative expression which helps reduce stress levels. Also finally You will have a chance to turn your hobby into profitable business, selling what you create for wide audience.

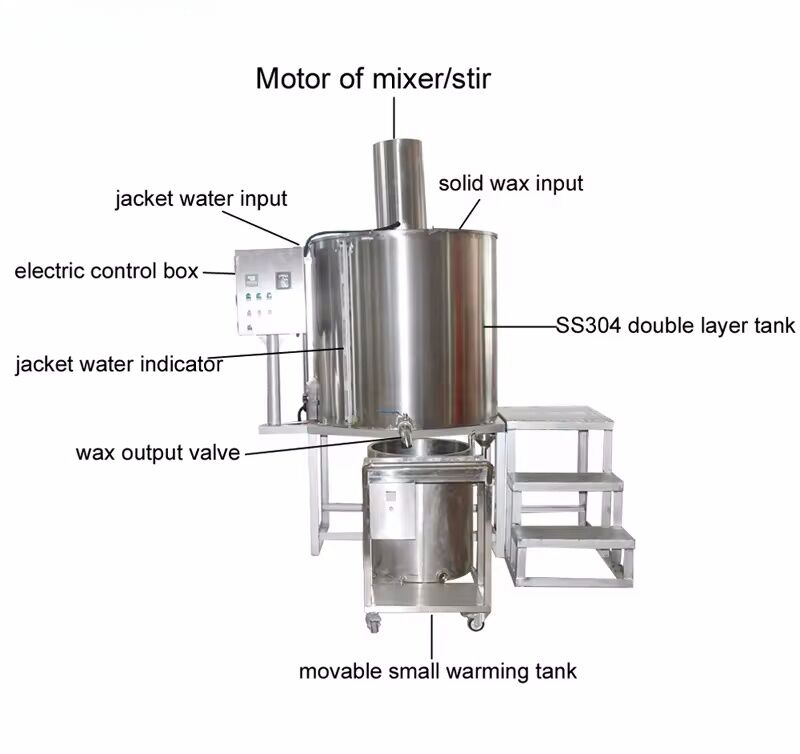

There has been a lot of improvement in the world of candle-related tools! So now, bid for farewell to traditional melting pots and candle molds that take up too much space in the house. Introducing revolutionary tools to make candle-making easier. New electric wax melters enable quick and safe milling of the wax, digital scales assure perfect measure in a quantity for each candle(runtime), be it scent or coloured. Wick centering tools also help keep the wick centered in your mold. In addition to the physical tools, process sparks are a plethora of online resources and communities offering valuable insights on candle-making.

Although making candles is a very fun process you need to remember that safety comes first. Ensure you take the necessary precautions to wear gloves and safety glasses when dealing with molten wax or fragrance oils. Always keep an eye on the wax when it is melting, as melted wanes are a fire hazard. Always keep a close eye on the wax temperature with a thermometer, as overheating can cause it to ignite. Finally, make sure to properly ventilate your area so you do not inhale fumes.

Candle-making tools are a very simple task - but they need to be done carefully, and you have to practice patience. The process starts with your choice of wax and desired fragrance, you then measure the right quantity based on how large your mould is be used in placing it into an electric Wax Melter. Once the desired temperature is reached, add in your scent and mix well. Centre the wick in the mold and carefully pour your wax blend over. Once the wax has cooled and hardened, remove from mould and then trim wick to desired length.

equipment made stainless steel food-grade resistant corrosion, anti-rust, resistant high temperatures.order ensure precision effectiveness ensure accuracy efficiency, stepper motor as well servo motors substituted normal motor. pump constructed food grade stainless steel type 316, instead steel plastic.There different sizes pumps, such Equipment needed to make candles/6L/10L 20L accommodate different filling capacities. Touch screen desgin PLC simple set parameters such as filling frequency, filling speed temperatures, filling speed more. There's wide selection candle equipment available, not only semi-automatic kind also fully automated type. machines updated more adaptable durable.

With 1-year warranty lifetime maintenance service. professional inspection video pictures will sent clients Equipment needed to make candles shipment. After-sales problems resolved within 1 hour, solution will provided within 24 hours. customers appreciate experienced team foreign trade as well professional service. Also have professional RD department which transform ideas actual machine. Production department responsible each stage production point receive goods.

Dongguan Yide Machinery Co.,Ltd specializes candle machine manufacturing. most popular products wax melting tank, wax-filling machine wicking machines. have more Equipment needed to make candles semi-automatic candle machines stock, two fully automatic lines kept stock.

Three Equipment needed to make candles employees 8 steps quality checks ensure machine 100% reaching standards safety using.With experienced RD team comprising 5 members offer custom solution 48 hours. perfect machine your candle-making business. We able build machine precisely your specifications, just meet requirements